Reducing clinker and boosting performance: Omya’s minerals

Omya is a leading global producer of essential minerals and a worldwide distributor of specialty materials. Founded in Switzerland in 1884, it extends in 160 locations in 50 countries. We operate in all markets using sustainable minerals to promote a collective responsibility mindset and provide innovative solutions which meet and foster the needs of current and future generations.

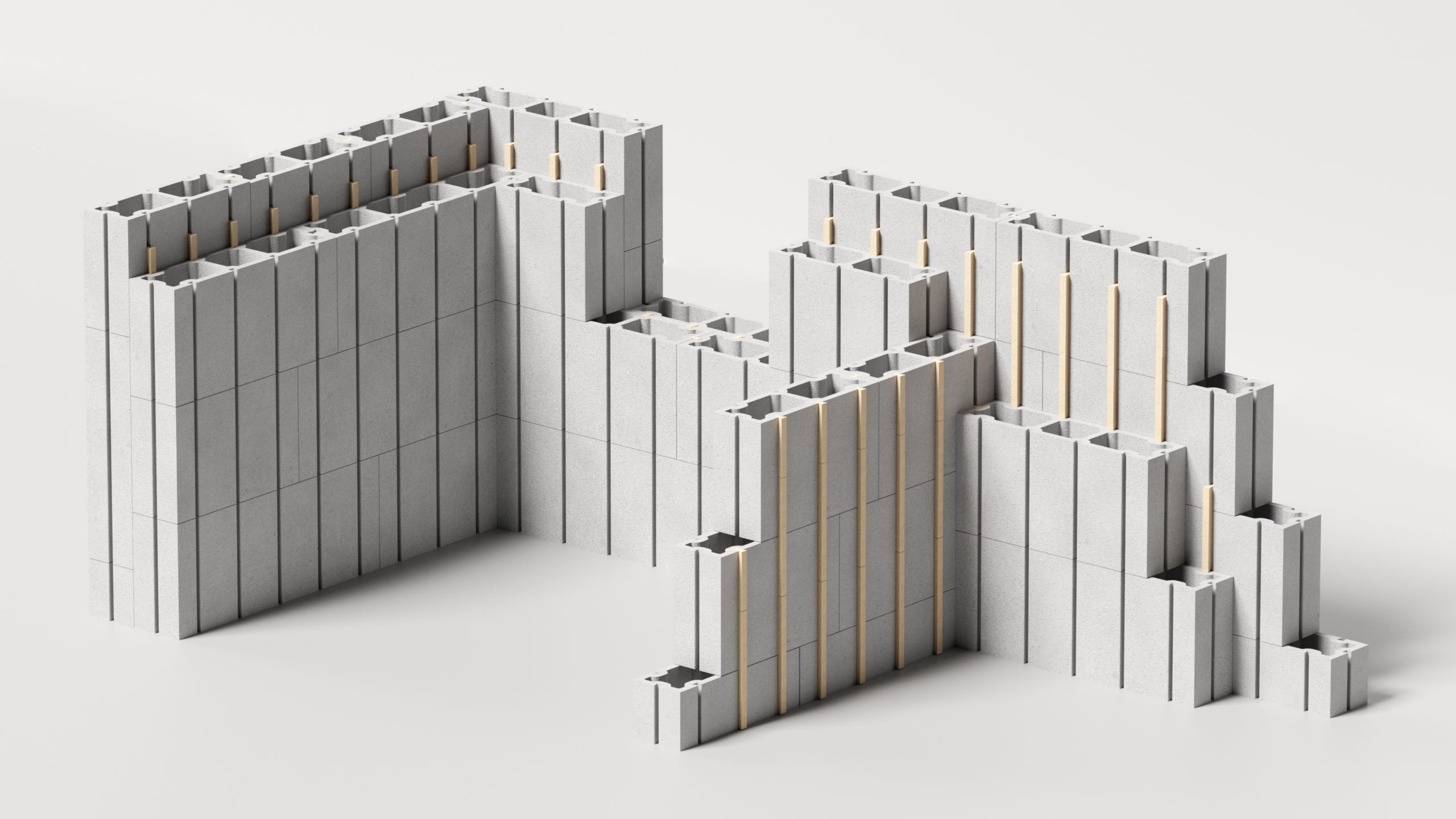

In line with the current struggle of the concrete market, which is focused on finding solutions for the notably high percentage contribution to global carbon emissions (8%, as documented by the International Energy Association, IEA), Omya passionately supports the manufacturers of cement and concrete and market players in providing the best solutions for a more sustainable Construction Industry.

The mineral admixtures of the Betocarb and Betoflow grades have been engineered to improve the performance and sustainability profile of concrete and cement with low carbon footprint.

Omya supports the use of eco-concrete, offering a much lower carbon footprint than conventional concrete by reducing the clinker to cement ratio.

Betocarb line: sustainable synergy

The carbon footprint can be significantly reduced by using low carbon cements with a reduced clinker factor or a combination of cement and supplementary cementitious materials (SCMs) such as natural pozzolan, fly ash, calcined clay, glass powder or blast furnace slag.

Omya’s Betocarb product portfolio supports this reduction in carbon footprint of cements and/or mortars and concrete, providing synergies with SCM leading to optimisations in water requirement, workability, packing and resistance to segregation.

Higher performance products

Our range of mineral plasticisers and mineral accelerators helps concrete producers deliver higher performance products by improving stability, flowability, optical properties and consistency.

- Optimised packing for greater stability through increased paste content and void filling

- Optimised fines content, yielding higher rheological stability, reduced segregation and better flowability

- Increased early strength, leading to higher throughput

Talk to us

With technical laboratories at our headquarters and dedicated regional technical service hubs , Omya offers laboratory analysis, reformulation support, and implementation assistance to customers worldwide.

Contact us here.

Joining the ALCCC aligns with Omya's commitment to sustainable practices and collective action within the value chain. By collaborating with leading manufacturers and suppliers, leveraging our mineral admixtures for carbon footprint reduction, and actively participating in discussion tables on standards and scientific research, we aim to drive decarbonisation and contribute to a more sustainable future.Nadine Nicolai, Global Business Development Director Construction