C2CA Technology aims to phase out the use of virgin materials in concrete

Our member C2CA Technology aims to phase out the use of virgin materials in concrete – read on to learn how.

Cement accounts for 8% of global CO2 emissions, contributing to climate change. Moreover, two billion tonnes of concrete waste are produced yearly – waste containing polluting materials, including plastic, and only downcycling or landfilling processes are available. Downcycling occurs when the recovered concrete lacks the necessary characteristics to be reused in similar structures or recycled to produce liquid concrete.

Solution – turning concrete rubble into new materials

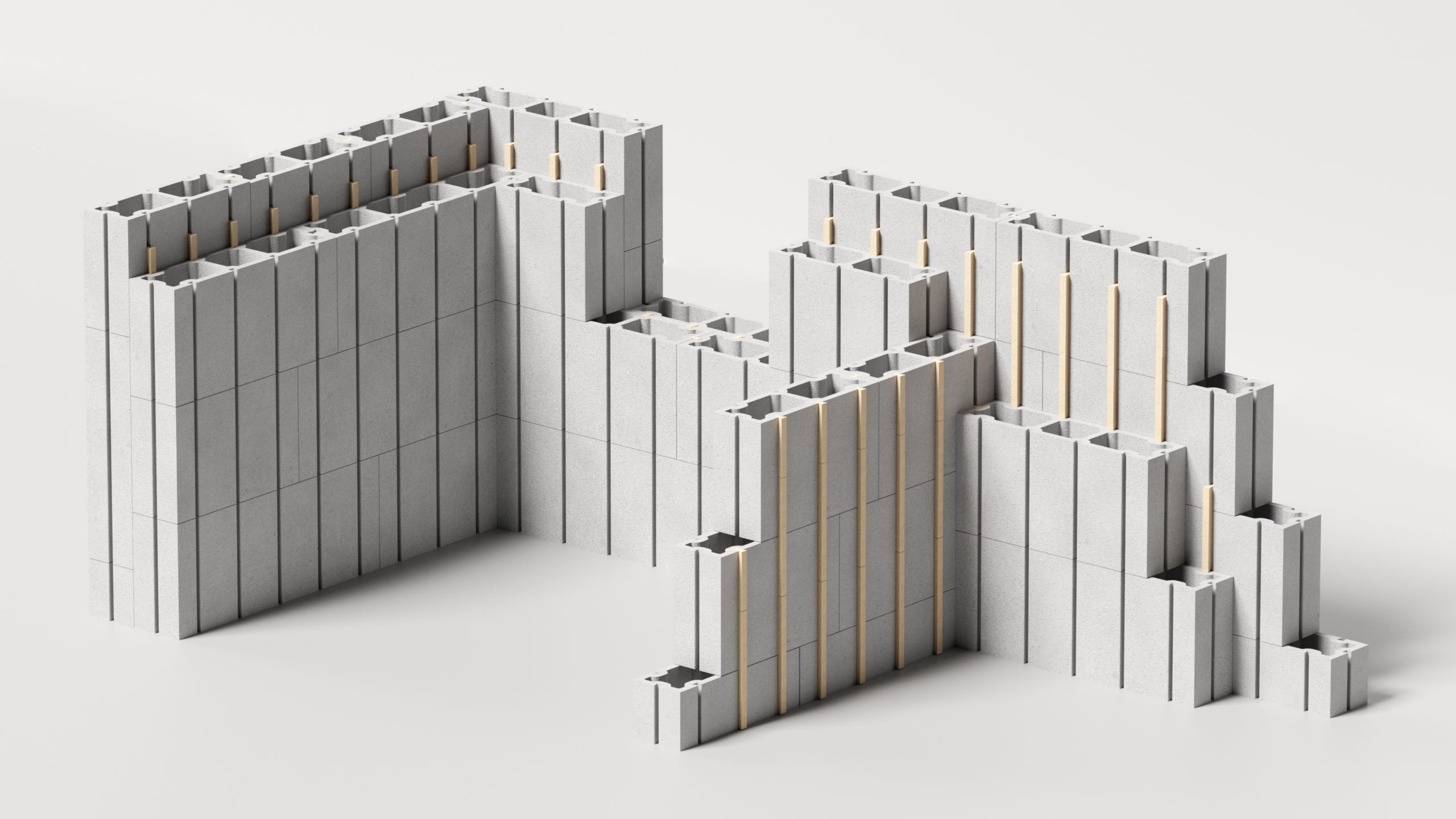

C2CA Technology, in collaboration with GBN Group and TU Delft, aims to transform the construction industry with its ground-breaking circular concrete technology. By turning concrete rubble into new materials for new concrete, C2CA uses density and thermal/cracking separation techniques to produce recycled aggregates, sand, and cement substitutes. This innovation earned C2CA the 2021 Innovation Radar Prize for the most promising EU-financed innovation.

Aiming to make concrete 100% circular, C2CA plans to disrupt the centralised production model and convert 2 billion tonnes of waste concrete into 1 billion tonnes of aggregate, 0.6 billion tonnes of sand, and 0.4 billion tonnes of cement substitute, yielding significant environmental benefits.

Driving change with Dutch strong targets – C2CA’s circular concrete

Currently, C2CA Technology has a strong focus on The Netherlands – a country which is taking a well-balanced approach to its plans for a rapid transition to a carbon-neutral economy that will support strong growth and energy security. To drive this ambitious shift, the Dutch Government aims for a 49% CO2 reduction by 2030, and 95% by 2050 – compared to 1990 levels. Moreover, Netherlands Circular targets a 50% reduction in primary resources by 2030 and 100% circularity by 2050.

Under the Dutch Klimaatenveloppe initiative, C2CA collaborates with different partners to research material properties of Recycled Concrete Aggregate (RCA), Recycled Fine Aggregate (RFA), and Recycled Cement Paste (RCP)/Recycled Concrete Fines (RCF). Recycling 10-20% of end-of-life concrete and upcycling it as a clinker replacement can substantially reduce CO2 emissions: 21%-42% in the EU and 10%-20% globally, amounting to a 140–280-million-tonne reduction.

C2CA’s circular concrete has been successfully implemented in various projects – including Green Village (at TU Delft campus.), LEVVEL blocks (Afsluitdijk), platform walls at Bunder station (ProRail), Butterfly blocks (ProRail), pavement stones (Rotterdam municipality), and Blue Carpet (Groningen).

We're ecstatic to join the ALCCC, a crucial initiative promoting low-carbon cement and concrete solutions. C2CA is dedicated to transforming the industry with circularity, fostering substantial environmental benefits. Accelerating standards reform is vital for a swift, sustainable transition in this sector.Thomas Petithuguenin, CEO, C2CA Technology

Get to know us better – C2CA Technology and the Alliance for Low-Carbon Cement and Concrete

C2CA Technology, a company which began as a collaboration between GBN Group and TU Delft, aims to transform the construction industry with its groundbreaking circular concrete technology. By turning concrete rubble into new materials for new concrete, C2CA uses density and thermal/cracking separation techniques to produce recycled aggregates, sand, and cement substitutes. This innovation earned C2CA the 2021 Innovation Radar Prize for the most promising EU-financed innovation. Learn more about C2CA here.

Our Alliance was created to steer the sector towards viable decarbonisation pathways. Our members represent mature materials designers and producers, and also start-ups working in biotechnology, capturing carbon, and sustainable construction. We are all rooted in the circular economy and sustainable construction, and we all share the desire to change our industry – and prevent catastrophic climate change.