A low-carbon alternative – cement that sequesters emissions by Concrete4Change

Take a look at how our member Concrete4Change works to create net-zero concrete, reducing harm to the planet as a result.

If concrete were a country, it would be the world’s third biggest emitter of CO2. After water, concrete is the second most-consumed material on the planet. Cement is also the major source of pollution in concrete – responsible for up to 75% of emissions. In order to make the green transition a reality, safe and cost-effective low-carbon solutions need to be deployed at scale.

Concrete4Change is a R&D focused deep-tech start-up developing novel technology for carbon sequestration in concrete, helping the concrete industry achieve net-zero. C4C has conducted several projects and trials with prestigious concrete manufacturers, construction companies and research organisations.

The proof-of-concept was successfully completed in January 2022, with the University of Warwick conducting an independent third-party test to verify the principles of the C4C carrier technology utilised in concrete samples. The test examined the rheology of the wet mix, compressive strength of cured parts (multiple curing times in the range 1-28 days), and chemical composition. C4C found uniform carbonation (1.5% CO2 by the weight of cement), an increase in compressive strength at 28 days at an average of 15%, and no significant change in pH (pH in the range 12-13 for all samples, including controls).

In March 2022, C4C then completed its first industrial trial with the largest ready-mix concrete manufacturer in the UK, Hanson. Two 1 tonne concrete moulds were cast using the C4C carrier. The moulds formed part of a sustainable hoarding system for a live construction project in London.

C4C is backed by two of the largest concrete manufacturers, who are two of the investors in the company: Goldbeck, the largest pre-cast concrete manufacturer in the EU, and Siam Cement Group – the 5th biggest concrete manufacturer in the world. Siam recently conducted its own internal tests of the latest prototype of C4C carrier technology, confirming the results of C4C’s internal tests and showcasing the potential of the carrier to successfully and reliably sequester CO2 in concrete.

C4C aims to scale up its technological readiness level in 2024, in readiness for commercial deployment in 2025.

The Alliance is essential because it is important to accelerate the pace of change in the industry. Innovations have been stifled by regulation and the industry has not adopted new technologies at the required speed and scale to reach the world’s net-zero target. The alliance will be a key player in helping foster the change that we need to reach true net-zero.Dalraj Nijjar, Co-founder, Concrete4Change

Get to know us better – Concrete4Change and the Alliance for Low-Carbon Cement and Concrete

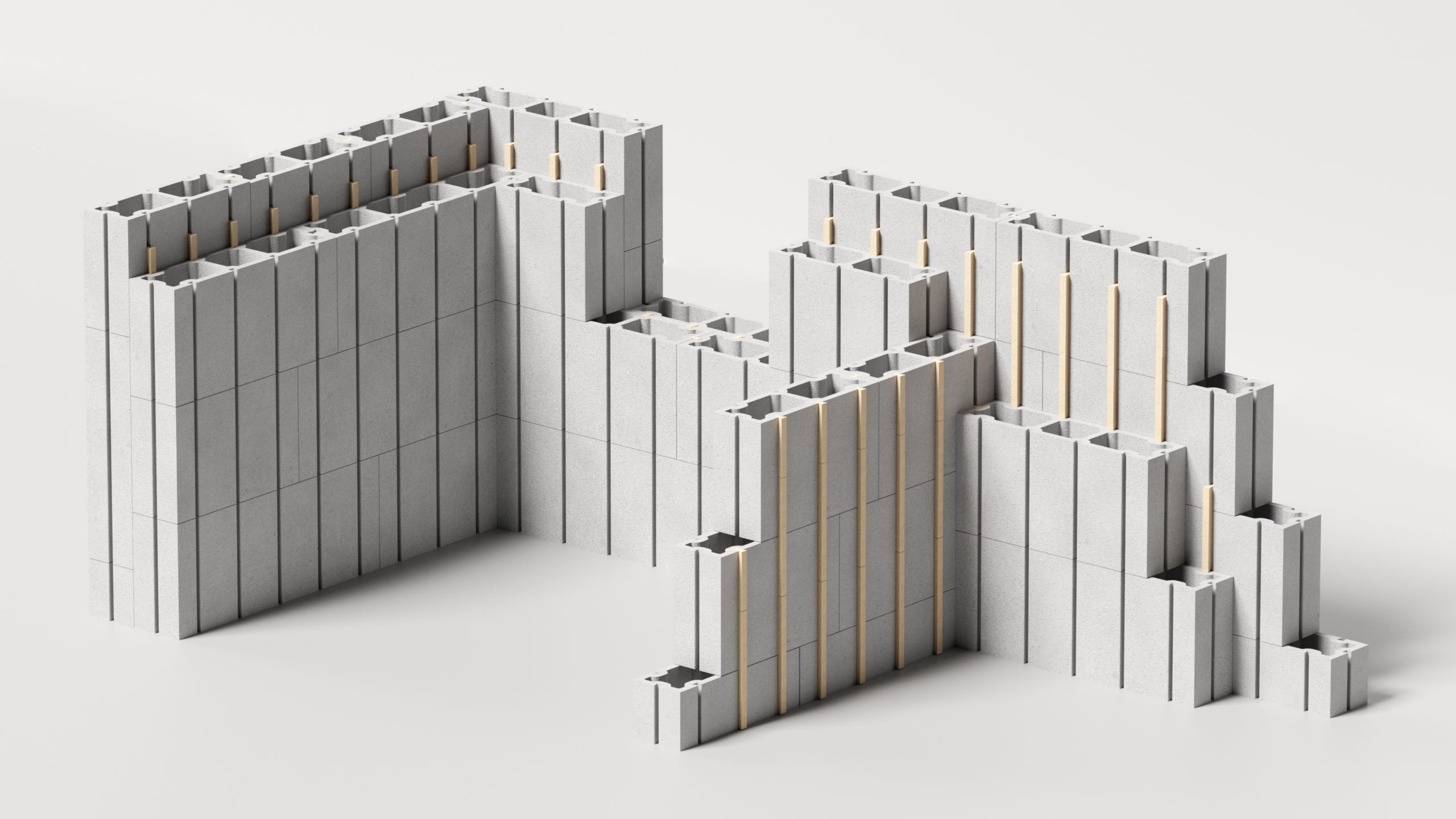

Concrete4Change (C4C) is an R&D licensing company, helping concrete manufacturers and the construction industry achieve net zero carbon neutrality. C4C’s technology incorporates a solid-state carrier to transfer CO2 into concrete – The CO2 reacts with the concrete to become permanently mineralised. So even in the event of demolition, there is no leakage of CO2. As a result of the mineralisation, the strength of the concrete will increase. Hence, the cement content can be reduced to produced equivalent-strength concrete. C4C technology was included in the prestigious Startups 100 list by Startups.co.uk for 2023, and was also awarded by the United Nations COP26 Climate Challenge Cup. Learn more about C4C here.

Our Alliance was created to steer the sector towards viable decarbonisation pathways. Our members represent mature materials designers and producers and also start-ups working in biotechnology, capturing carbon, and sustainable construction. We are all rooted in the circular economy and sustainable construction, and we all share the desire to change our industry – and prevent catastrophic climate change.