Introducing NeoCem: Upcycling waste clays

Awarded the France 2030 label, NeoCem designs and operates industrial sites producing low-carbon cement in the northern half of France.

Two levers are simultaneously activated to reduce the carbon footprint of traditional cement (aka “clinker”) by ninefold: [95 kg CO2 per ton of NeoCem cement] versus [881 kg CO2 per ton of traditional cement]!

- Replace the limestone raw material sourced from quarries with upcycled clays from demolition/construction sites = Our main partner since 2019 has been the Société du Grand Paris;

- Heat less and for a shorter time using an innovative flash calcination process in a fluidized bed = [750°C for 20 seconds] vs. [1450°C for several hours] for the traditional cement process.

COMPETITIVE IMPACT AT SCALE

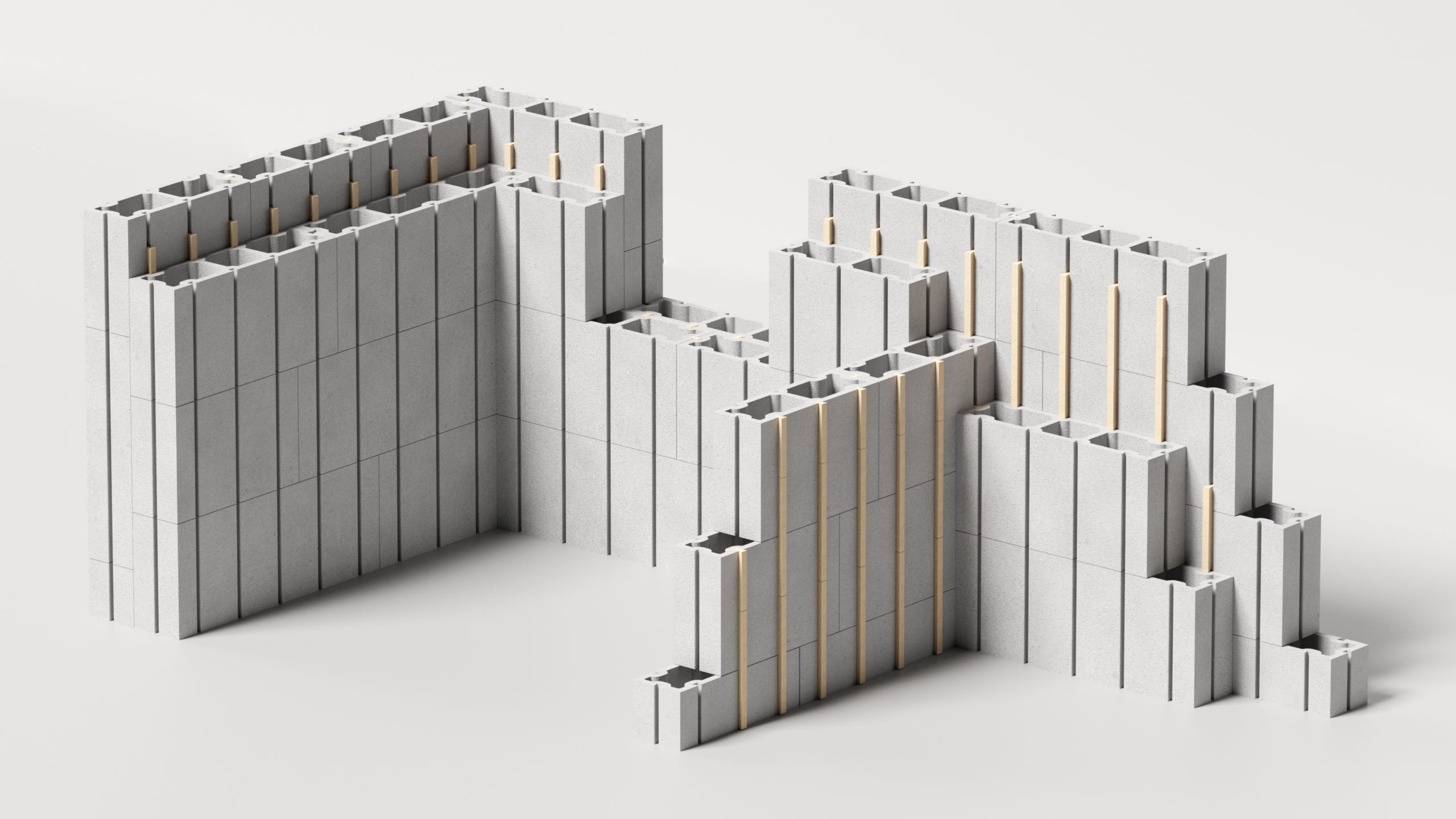

A NeoCem production unit with an annual capacity of 200,000 tons avoids the emission of 143,000 tons of CO2 each year. With an avoidance cost of around 15-20 €/tCO2 avoided vs. 150-200 €/tCO2 avoided for Carbon Capture, Storage, and Utilization technologies, the NeoCem solution is considered by ADEME and BPI to be “the most effective decarbonization solution for the heavy industry per Euro invested” identified to date. After 7 years of R&D, which led to the patenting of the technical solution (notably in partnership with the Société du Grand Paris) and achieving a technological maturity level validating scale production (TRL index 8), the first unit is under construction at the site of a former quarry being rehabilitated in Saint-Maximin, 30km from Paris in the Oise department (60), with a ramp-up beginning in Q2 2025.

2023 SERIES A PAVES THE WAY TO 2025 SERIES B

This is made possible by the closure of a first round of financing in 2023 supported by (i) three investment funds from Hauts-de-France (Rev3, Finorpa, NFA); (ii) three national banks formed into a banking pool (CIC, CA, Banque Postale); (iii) BPI and ADEME via the France 2030 scheme; and (iv) a major industrial partner operating in the cement industry.

A Series B is in advanced discussions to fuel the industrial deployment strategy for the next four NeoCem sites by 2030. It is based on three pillars: (i) a favorable geological context, with the presence of clay lithologies in the top 20-30 meters; (ii) a dense network of potential partners for the development of joint ventures, with earthmoving, extraction, concrete prefabrication, or ready-mix concrete industries, for example; and finally, (iii) a land reserve suitable for NeoCem’s clay recycling activity. As of Q3 2024, 20+ sites are under advanced discussions for JV deployment in Europe.

Guillaume Luu, Industrial Deployment Director, NeoCem, said:

At NeoCem, we pride ourselves of being mud alchemists – two feet on the ground; head in the stars #PragmaticDreamers

Indeed, we leverage top notch technologies mature at industrial scale – flash calcination #OurCauldron

To upcycle the most hated and common raw material on Earth – abrasive and sticky clays #YourLead

In order to produce the most desired and consumed commodity in the world – concrete via decarbonised clay based cement #YourGold

Join the #MudTech!

IN THE PRESS

Décarbonation : NeoCem lance une unité de production d’argiles calcinées dans l’Oise | Les Echos

NeoCem bétonne ses ressources financières | La Gazette Nord-Pas de Calais (gazettenpdc.fr)

GET IN TOUCH

Guillaume LUU, Industrial Deployment Director: gluu@neocem.com